Engineering Strength and Precision in Steel Castings

Eagle Alloy’s case studies showcase how advanced Airset and Shell mold casting processes solve complex design challenges, reduce costs, and improve part performance. Explore how engineering, simulation, and process control come together in real-world applications.

Latest Case Studies

Keeping Castings Made in America: Supporting the American Foundry Industry Through Entrepreneurship

This article on “Keeping Castings Made in America” describes how the three Eagle Group companies work with other innovative manufacturing companies to create demand for U.S.-made castings, thereby strengthening the domestic foundry industry and keeping more manufacturing within the United States.

All Case Studies

Miracle in Muskegon: How the Eagle Group Replicated a Mig 17F Fighter Jet Fuel Cap in Two Days

This case study article shares how the Eagle Group replicated a MiG-17F fighter jet fuel cap in under 48 hours, delivering a replacement part on short notice that enabled the historic jet to fly again.

Case Study: Converting a Fully Machined Part to an Investment Casting

This article describes a case study where the Eagle Group saw an opportunity to boost efficiency and achieve cost savings for a customer by converting a fully machined part into an investment casting.

Hydrant Guard Case Study: Concept to Completion Manufacturing by the Eagle Group

This case study article details how Eagle Group teamed up as a manufacturing partner with Hydrant Guard, a rising start in the water industry, to turn their water-saving check valve from concept to finished product and create a real-world solution to wet-barrel hydrant shears.

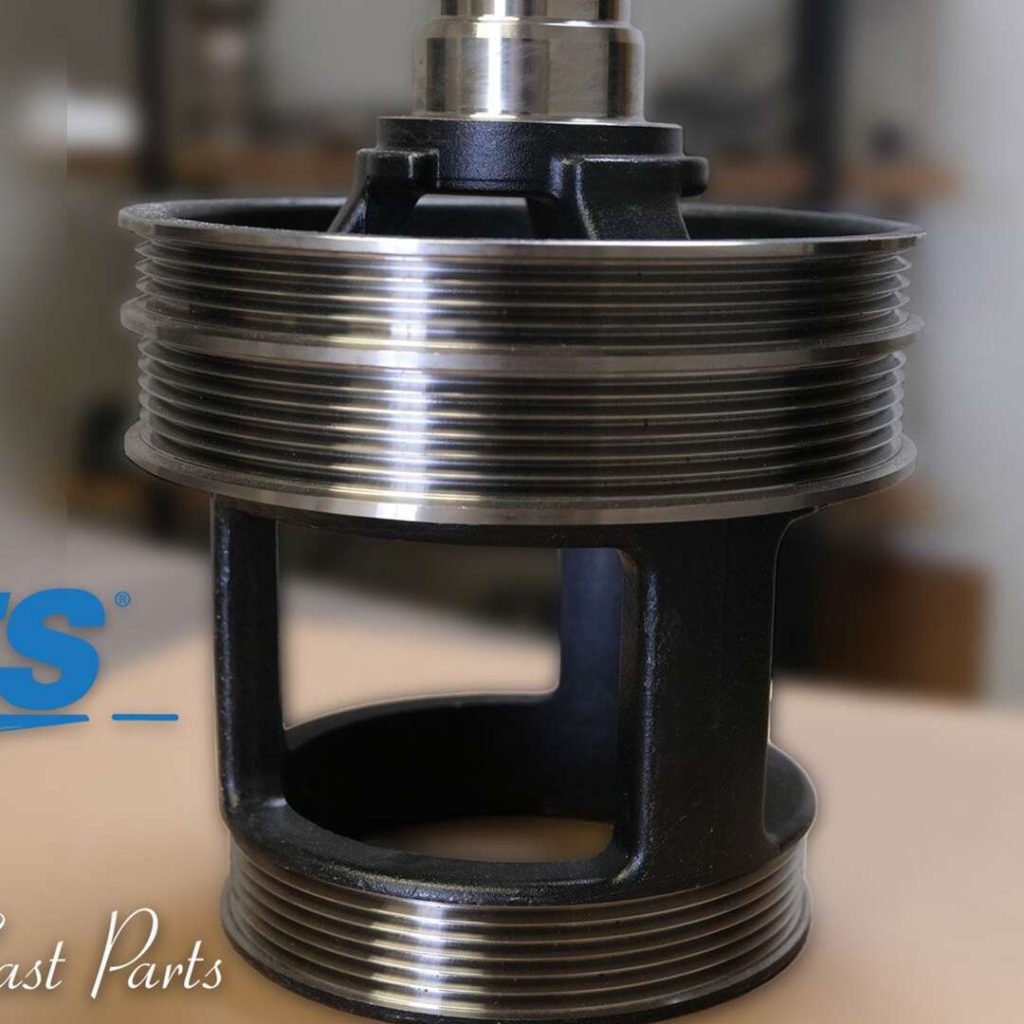

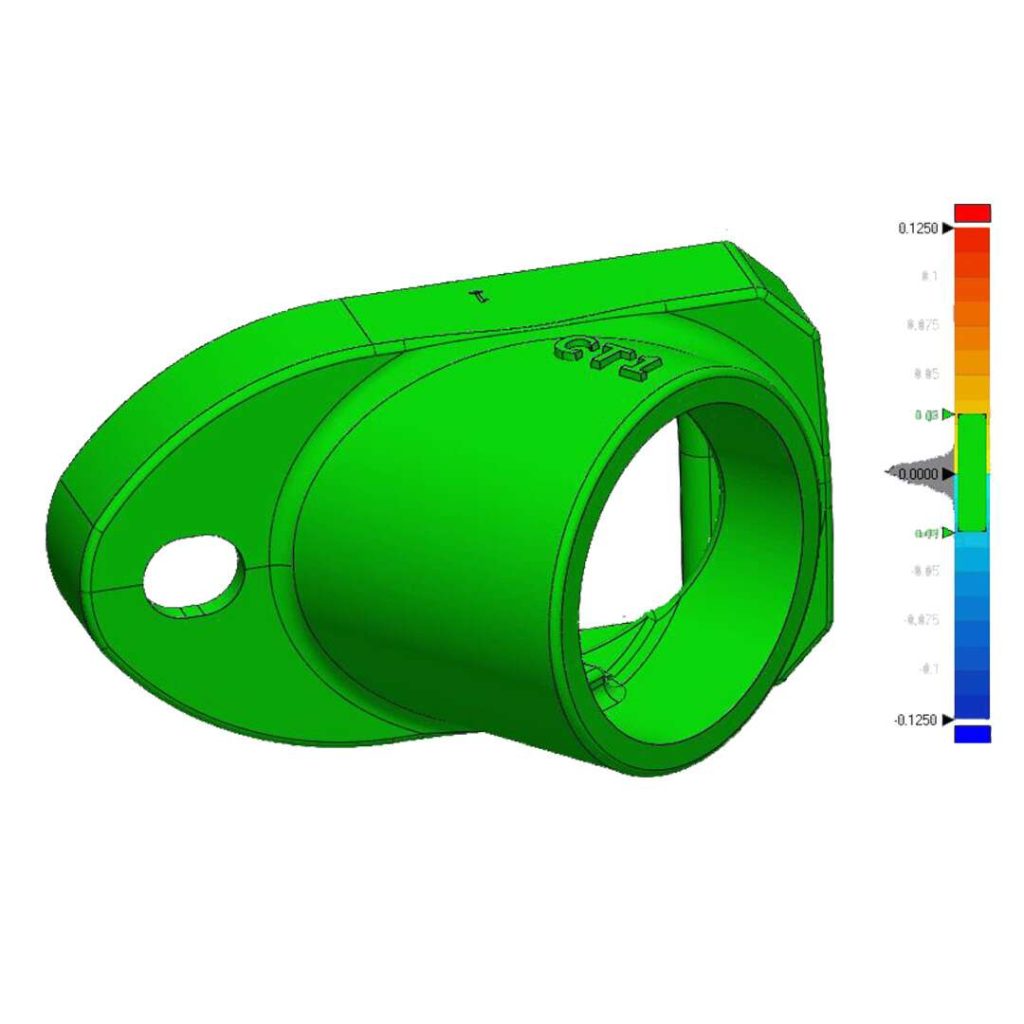

Case Study: Reverse Engineering Cast Products on an Expedited Timeline

This case study downloadable PDF shows how Eagle Alloy quickly reverse-engineered a cast product to meet an emergency order caused by a supply chain disruption, ensuring the manufacturer’s customers received the product without delay.

Case Study: Lean Manufacturing at Eagle Alloy

This Eagle Alloy case study article shows how lean manufacturing — 5S, cellular manufacturing, continuous flow, and takt time — led to 98-99% on-time delivery, boosted efficiency, and improved and overall part quality, highlighting their continuous improvement journey.

One Part’s Journey From Fabrication to Casting

This case study article shows how Eagle Precision led a fabrication-to-casting conversion that enhanced the original part, saved their client over $100 per part, and resulted in higher profit margins.