Precision Casting Services for Complex Parts

At the Eagle Group, our custom casting services are designed to deliver high-quality metal components that meet exacting tolerances. We can scale operations from a single prototype to high-volume production runs. As a vertically integrated manufacturer, we offer multiple casting methods backed by decades of experience and in-house engineering support.

Our team works with you from the earliest design stages, applying Value Engineering (VE) and Design for Manufacturability (DFM) principles to improve part performance and lower costs. Whether your part requires tight tolerances, cosmetic finishes, or complex internal geometries, we’ll match your requirements to the ideal casting method.

We offer four core casting methods to support a wide range of industries, part sizes, and design challenges. Click any option below to learn more.

Metalcasting Methods We Utilize

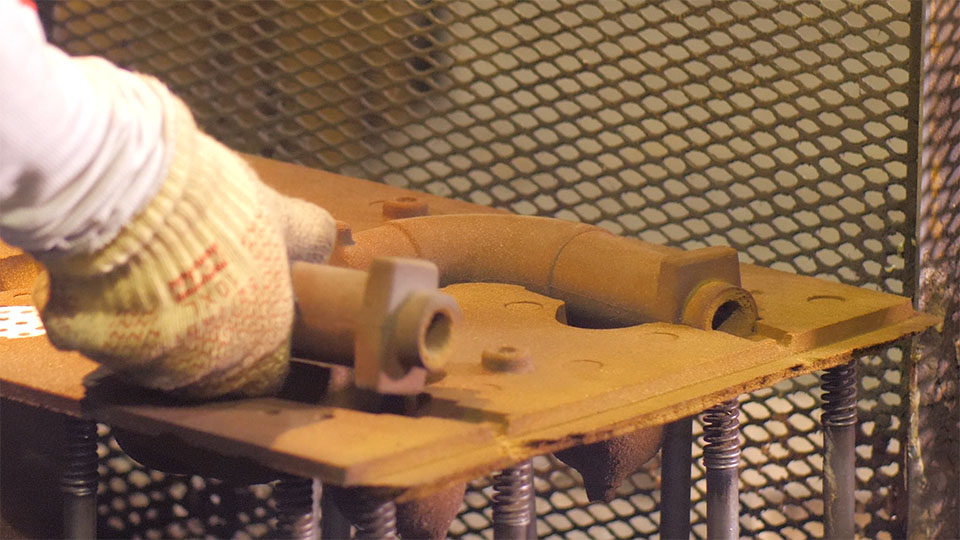

Shell Molding

Shell molding is a high-precision sand casting process ideal for medium to high volumes. It produces castings with excellent dimensional accuracy and surface finish—often requiring less post-processing than other sand methods.

Investment Casting

This process creates near-net-shape parts with intricate geometries and fine surface detail. It’s a great option for minimizing machining and cosmetic finishes in small to medium-sized parts.

Airset Casting

Airset or no-bake casting is best for larger, lower-volume parts and complex cores. It offers design flexibility with less tooling cost than high-volume processes, making it ideal for industrial components and prototypes.

Rapid Prototyping

For rapid prototyping and short runs, 3D printed molds eliminate the need for hard tooling. This method offers design freedom and faster turnaround times for complex or evolving part geometries.

Why Choose Eagle Group?

Collaborative Engineering Support

We work with customers from the start to align design, performance, and cost goals. Our engineers evaluate geometry, surface finish, and tolerance requirements to ensure every casting performs as intended. Early collaboration reduces rework, shortens lead times, and helps deliver quality castings that meet both technical and budget expectations.

Casting Simulation & Tooling Design

We use advanced simulation to refine gating and metal flow before production begins. This data-driven process improves yield, accuracy, and surface quality. Our engineers also design custom tooling and fixtures in-house, helping balance upfront tooling cost with long-term manufacturing efficiency and repeatable results.

Material & Process Selection

Choosing the right alloy and process is key to performance and value. Our team helps evaluate material requirements, production volumes, and surface finish needs while comparing shell, airset, investment, and 3D-printed mold options. Each recommendation is based on your project’s goals for cost, precision, and durability.

Integrated Machining & Quality Planning

Our vertically integrated operations combine machining, finishing, and quality planning under one roof. We provide complete PPAP documentation and dimensional verification using CMMs and laser scanning. This closed-loop approach ensures every part meets print, performs reliably, and arrives ready for assembly.

Casting Capabilities & Process Range

The Eagle Group’s foundries support a wide range of part sizes, tolerances, and finishes to match diverse project needs. Shell molding produces 2–400 lb castings with ±0.030″ accuracy and 150–300 RMS finishes. Investment casting offers fine detail for 1 oz–85 lb parts at ±0.005″ and 125 RMS. For larger, more complex designs, airset casting and 3D-printed molds handle up to 400 lbs with ±0.063″ tolerance and 350–560 RMS finishes. Each process delivers unique benefits in strength, precision, and cost efficiency.

Let’s Talk About Your Next Casting Project

Whether you’re refining an existing design or launching something new, Eagle Group’s custom casting services deliver the precision, speed, and flexibility you need.

Contact our team to get started or request a quote to tell us more about your needs.