Flexible and Reliable Airset Casting Solutions

Airset molding, or no-bake casting, is a sand casting method that creates molds from chemically bonded sand. Unlike shell molds, airset molds do not need to be pre-heated to solidify. Compared to other sand casting methods, like greensand, airset casting can offer better surface finish and tighter dimensional tolerances.

At Eagle Alloy, our custom airset casting capabilities support a range of part sizes and metals, which are ideal for prototypes and low- to medium-volume runs.

What Is Airset Molding?

Airset molding uses chemically bonded sand to form molds and cores for casting. Unlike greensand casting, which relies on moisture and clay, airset molds use a two-part resin system that hardens at room temperature. This allows for finer sand grains, sharper detail, and more consistent mold strength. The result is a casting process that delivers high-quality parts with fewer defects and tighter tolerances.

Our airset casting process regularly produces parts with:

- Dimensional control: standard tolerances of ±0.063″ per inch

- Surface finish: typically 350-560 RMS

- Part size range: ideal for components from 2 lb to 400 lb, with overall sizes up to 30″×40″×14″

Airset molds are a strong choice for parts that require both strength and precision without the tooling investment associated with shell or investment casting.

Benefits of Airset Molding

Manufacturers choose airset molding for its balance of flexibility, durability, and cost efficiency.

Key advantages include:

- Excellent Dimensional Accuracy: Achieves tight tolerances compared to other sand casting methods.

- Lower Tooling Costs: Requires less expensive tooling than shell molding processes.

- Reduced Machining Requirements: Produces smoother as-cast surfaces, cutting down finishing time.

- Versatile Material Options: Suitable for a wide range of ferrous and non-ferrous alloys.

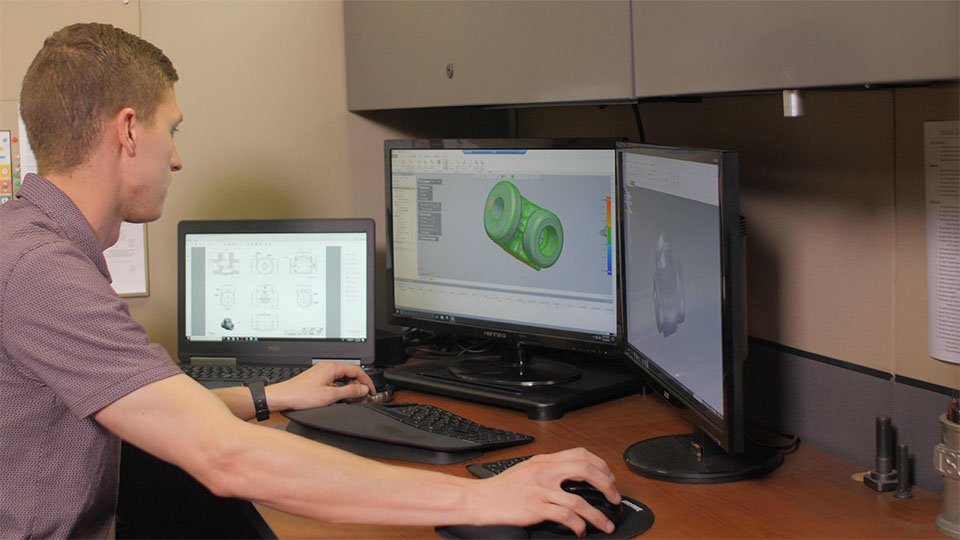

Design Support and Engineering Services

Eagle Alloy’s experienced engineering team collaborates closely with your designers to ensure every casting is optimized for performance and manufacturability. We use advanced simulation software to evaluate gating, cooling, and mold filling, which allows us to fine-tune designs before production begins.

For a deeper dive into our process, view the Eagle Alloy PDF:

Airset Casting Compared to Other Metal Casting Methods

| CASTING METHOD | TOOLING COSTS | LABOR COSTS | TYPICAL TOLERANCES | SURFACE FINISH | TYPICAL VOLUME |

|---|---|---|---|---|---|

| Airset Casting | Low | High | ±0.063″ | Fair | Low |

| Investment Casting | Medium | High | ±0.005″ | Very Good | Low to High |

| Shell Mold Casting | Medium | Medium | ±0.030″ | Good | Medium |

| Greensand Casting | Low | Medium | ±0.030″ | Fair | Low to Medium |

Start Your Airset Casting Project

Eagle Alloy delivers custom airset castings focusing on dimensional accuracy, material consistency, and collaborative engineering. Whether you need prototypes or low-to-medium volume runs, our team is ready to support your goals with reliable, U.S.-based casting services.

Request a Quote or Contact Our Team to learn more about our airset molding capabilities.