Accurate and Intricate Parts with Investment Casting

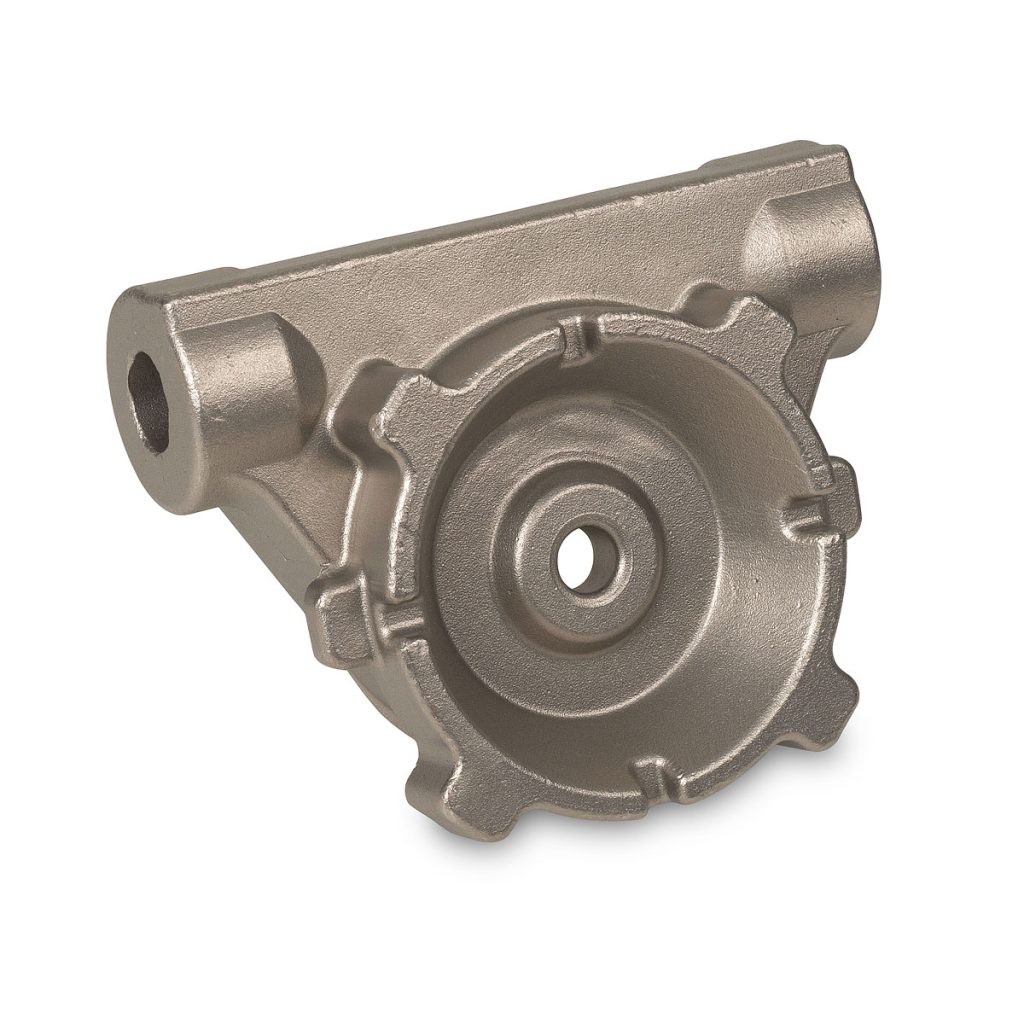

Investment casting is one of the most precise and versatile metalcasting methods available. Also known as “lost wax casting,” the investment casting process creates near-net-shape components with tight dimensional tolerances and excellent surface finishes.

The Eagle Group utilizes this method to produce complex parts that meet exacting customer standards across various industries, including defense, energy, food equipment, transportation, and medical.

What Is the Investment Casting Process?

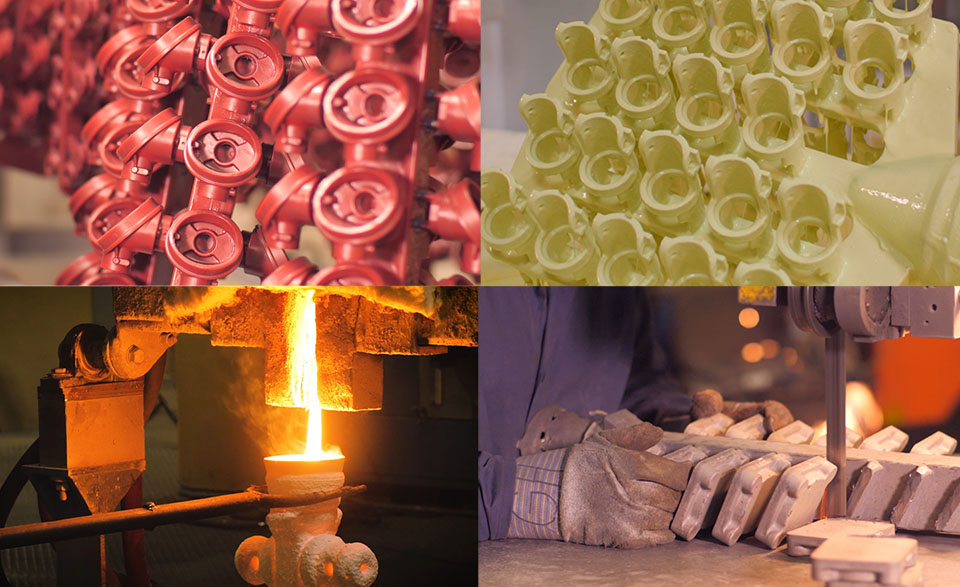

Investment casting begins with a wax pattern, which is coated in ceramic slurry to form a mold. Once the ceramic hardens, the wax is melted out, and molten metal is poured into the mold. After cooling, we break the ceramic shell away, revealing the cast part.

This method supports:

- Intricate internal cavities and fine detail

- Near-net-shape geometries to minimize machining

- A wide variety of alloys, including stainless steel, nickel alloys, and tool steels

The Eagle Group’s investment casting foundry, Eagle Precision(insert link), uses this process to produce parts with surface finishes around 125 RMS and tolerances of ±0.005″ per inch. Typical part weights range from 1 oz to 85 lbs, with maximum part dimensions up to 24” x 24”.

When to Choose Investment Casting

Investment casting is ideal when your project requires:

- High-dimensional accuracy

- Smooth finishes with minimal post-processing

- Complex geometries that would be difficult to machine or fabricate

- Cost reduction opportunities through fab-to-casting conversion

Many of our customers convert fabricated and fully machined parts to cast parts to streamline production and reduce costs. Learn more about this approach in our free Investment Casting Process Guide, which includes a fabrication-to-casting case study.

Materials We Cast

We support a wide range of materials, including:

- Stainless steels

- Carbon and alloy steels

- Bronze and brass

- Aluminum alloys

- Nickel-based superalloys

For more details, refer to our downloadable Investment Casting Quick Reference Guide, which includes dimensional tolerances, material options, and design tips.

Investment Casting at the Eagle Group

Eagle Precision Cast Parts, a member of the Eagle Group, specializes in investment casting using both ferrous and non-ferrous metals. Located on our Muskegon, MI campus, Eagle Precision produces parts for over twelve unique industries and partners closely with our [CNC machining team](insert link to Eagle CNC Technologies) to deliver fully finished components.

We routinely provide:

- Wax tooling design and production

- Alloy selection support

- Surface finish enhancements

- Heat treatment and inspection

- Conversion from fabricated assemblies to castings

Our process minimizes rework and accelerates time to market for intricate parts.

Investment Casting Compared to Other Metal Casting Methods

| CASTING METHOD | TOOLING COSTS | LABOR COSTS | TYPICAL TOLERANCES | SURFACE FINISH | TYPICAL VOLUME |

|---|---|---|---|---|---|

| Investment Casting | Medium | High | ±0.005″ | Very Good | Low to High |

| Shell Mold Casting | Medium | Medium | ±0.030″ | Good | Medium |

| Greensand Casting | Low | Medium | ±0.030″ | Fair | Low to Medium |

| Airset Casting | Low | High | ±0.063″ | Fair | Low |

Investment casting offers tighter tolerances and smoother finishes than other casting methods, particularly for complex, low-volume parts. While it may carry higher labor costs, its precision and repeatability often reduce or eliminate the need for secondary operations.

Ready to Get Started?

Contact the Eagle Group to explore whether the investment casting process is the right fit for your project. Our engineering team will guide you through feasibility, design recommendations, and production planning to ensure optimal results.