Accelerate Development with Rapid Prototyping

When time and flexibility matter most, rapid prototyping for casting offers a fast-track solution for producing complex metal parts in small quantities. At the Eagle Group, we use this advanced approach to support prototyping and low-volume production, helping customers refine designs and move quickly from concept to casting without the delays and costs of traditional tooling.

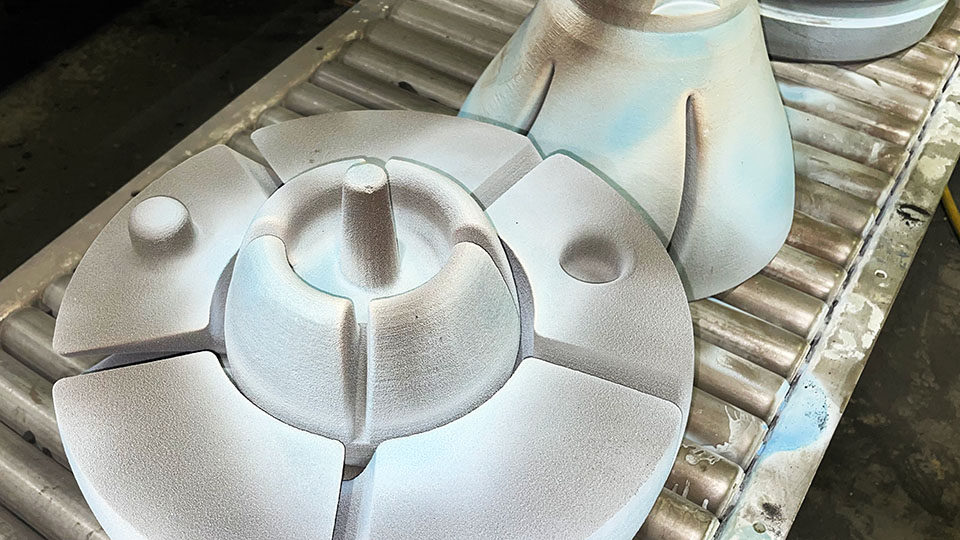

For rapid prototyping, Eagle Alloy often employs 3D-printed molding to save time and up-front tooling costs. We partner with trusted additive manufacturers, such as Humtown Additive, to directly integrate 3D-printed sand molds and cores into our foundry process. This allows us to deliver complete casting solutions using printed tooling—without compromising quality or lead time.

What Is Rapid Prototyping for Metalcasting?

Rapid prototyping for metalcasting combines additive manufacturing with traditional metalcasting processes. Eagle Alloy, the Eagle Group’s shell mold and airset foundry, employs 3D-printed sand molds for rapid prototyping of castings. Using a digital model of your part, specialized printers build sand molds and cores layer by layer. Once printed, the molds are cleaned, cured, and shipped to Eagle Alloy for pouring and finishing.

This tooling-free method is ideal for jobs that require fast iteration or only a limited number of parts. It also enables complex internal geometries that would be difficult or impossible to achieve with traditional core assemblies.

When to Use Rapid Prototyping for Metalcasting

This process works best when:

- You need to test a new design or material

- You want to avoid permanent tooling investment

- You require only a small number of pieces

- Your part design includes complex or undercut features

- Short lead times are critical to your development cycle

Dimensional Tolerances

- Linear: ±0.045″ per inch

- Angular: ±1 degree

Casting Characteristics

- Surface finish: 200–420 RMS

- Minimum wall thickness: 0.250″ (6.35mm)

- Typical part weights: 2–400 lbs

- Typical production quantity: 1–100 pieces per run

Inside the Rapid Prototyping Process

Our team uses in-house CAD and solidification simulation software to design mold geometry, gating systems, and pour strategies. We then coordinate with our additive manufacturing partners to produce sand molds and cores tailored to each job. Eagle Alloy then integrates these printed components to form complete molds and pours them using standard foundry practices.

Steps include:

- CAD model development and gating simulation

- Partner-supported 3D printing of sand cores/molds

- Assembly of printed molds and cores

- Casting using conventional pouring methods

- In-house dimensional verification via 3D scanning

Benefits and Considerations of Rapid Prototyping for Casting

Advantages

- No permanent tooling required

- Faster iterations with easy design changes

- Shorter development timelines

- Enables complex features and internal channels

Limitations

- Not cost-effective for high-volume production

- Surface finish depends on print resolution

- Part dimensions are limited by the printer size

- Print volume and material compatibility may limit the scope

Explore Rapid Prototyping for Your Next Casting Project

The Eagle Group leverages rapid prototyping for casting to help customers reduce tooling costs, speed up development cycles, and confidently validate designs. Let’s talk about whether this approach is right for your next project.