Shell Molding Castings for Reliable Performance

The shell molding process sets the standard for precision and consistency in metal castings. The Eagle Group’s shell molding foundry, Eagle Alloy, delivers high‑accuracy, complex components across industries all backed by decades of metalcasting know‑how and advanced manufacturing systems.

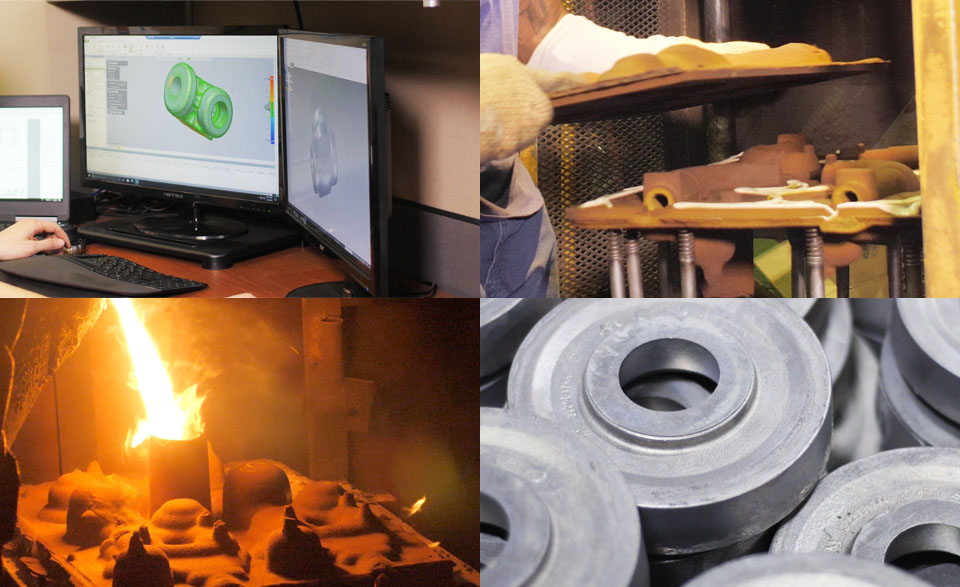

Our shell molding process begins when resin‑coated sand is applied to a heated metal pattern. The heat cures the sand to form a rigid shell that inherently offers smoother metal casting surfaces, tighter tolerance control, and repeatable quality compared to other sand casting methods.

WHAT IS the Shell Molding process?

Shell molding starts with a pattern, usually made of stainless steel for durability. The pattern is then heated and covered in a process-specific sand mixture, which is then heated to form strong bonds. Shell molds are combined with cores to form inner cavities, and molten metal is poured into the molds. After cooling, the sand shell is broken away to reveal the casting. Sand is captured, cleaned, and re-used by the foundry for new molds.

Shell molding process details include:

- Dimensional control: standard tolerances of ±0.030″ per inch

- Surface finish: typically 150–250 RMS

- Part size range: ideal for components from 2 lb to 400 lb, with overall sizes up to 30″×40″×14″

This method bridges the gap between sand and investment casting processes, offering excellent detail, surface quality, and cost efficiency without sacrificing repeatability.

Why Choose Shell Molding?

Dimensional Accuracy and Surface Quality

Shell molding produces crisp details like sharp lettering, thin sections, and smooth surface profiles, thanks to the heat‑bonded resin system. Our comprehensive control measures reduce the need for machining, helping lower total cost and cycle time.

Cost-Effective Tooling

Shell molding uses durable, reusable metal patterns and coreboxes to produce thin resin shells and cores. Since tooling does not come into contact directly with molten metal, materials are more flexible than with other casting methods like die and permanent mold.

Design Flexibility

We support intricate castings by incorporating shell cores and multi-part molds, which enable internal passages and undercuts without requiring post-cast assembly. Our team performs early Design for Manufacturability (DFM) reviews to optimize part geometry and process flow.

Ideal Applications for Shell Molding

Our shell molding services are best for:

- Medium- to high-volume parts in a wide range of steel or stainless steel alloys

- Specialized valves, pump housings, agricultural and construction equipment, and fluid-handling components

- Geometries requiring relatively thin walls with an emphasis on cosmetic detail

From prototype through full production, shell molding offers a balanced solution for manufacturers seeking high precision and repeatability.

![BY: kirk@cd-images.com [D800 #2]](https://v01p1qb30kz.c.updraftclone.com/wp-content/uploads/2025/11/Part04-EagleAlloy-14533r-1200x1200-1-1024x1024.jpg)

![BY: kirk@cd-images.com [D800 #2]](https://v01p1qb30kz.c.updraftclone.com/wp-content/uploads/2025/11/Part02-EagleAlloy-14528-1200x1200-1-1024x1024.jpg)

How We Manage Quality

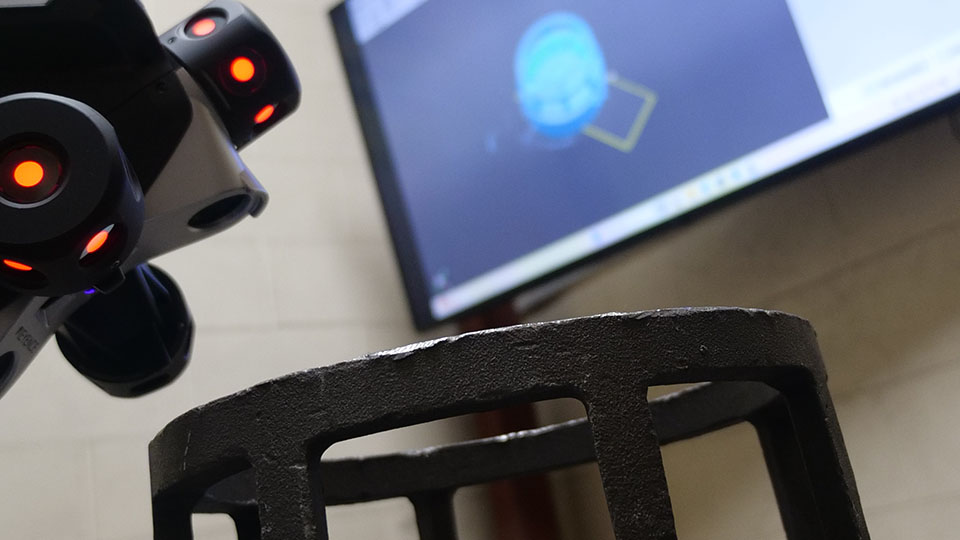

Precision isn’t an accident. We employ thorough quality steps throughout:

- Pattern Preparation: Fully inspect and preheat casting patterns

- Shell Building: Use controlled resin-sand mix and timed shell buildup cycles

- Core Production: Manufacture heat-cured resin cores for internal structures

- Pouring: Monitor metal temperature and pour rates for alloy-specific parameters

- Inspection: Use visual checks, CMM, and SPC reports to ensure dimensional compliance and surface integrity

As part of the Eagle Group, Eagle Alloy upholds ISO 9001:2015 quality standards so that every mold and casting traces back to batch records and material certifications.

Shell Mold Casting Compared to Other Methods

| CASTING METHOD | TOOLING COSTS | LABOR COSTS | TYPICAL TOLERANCES | SURFACE FINISH | TYPICAL VOLUME |

|---|---|---|---|---|---|

| Shell Mold Casting | Medium | Medium | ±0.030″ | Good | Medium |

| Investment Casting | Medium | High | ±0.005″ | Very Good | Low to High |

| Greensand Casting | Low | Medium | ±0.030″ | Fair | Low to Medium |

| Airset Casting | Low | High | ±0.063″ | Fair | Low |

Start Your Shell Molding Project

Leverage the Eagle Group’s shell molding process to produce high‑performing, reliable castings with precision and cost efficiency. Whether you’re engineering the next generation of valves or building industrial equipment, our team is ready to deliver.

Contact our experts today to explore if shell molding is right for your casting needs!