Complete CNC Machining Solutions from Prototype to Production

At the Eagle Group, we provide precision machining services for complex metal parts requiring tight tolerances, repeatable quality, and high-performance finishes. Whether you need prototype quantities, short-run batches, or full-scale production, we tailor every project to your specifications. Our in-house engineering, quality control, and material sourcing ensure your project is done right the first time.

Through our machining company, Eagle CNC Technologies, we bring advanced equipment, skilled operators, and vertically integrated support under one roof. You can rely on us for consistent performance, clear communication, and reliable lead times across every job.

In-House Capabilities & Support Services

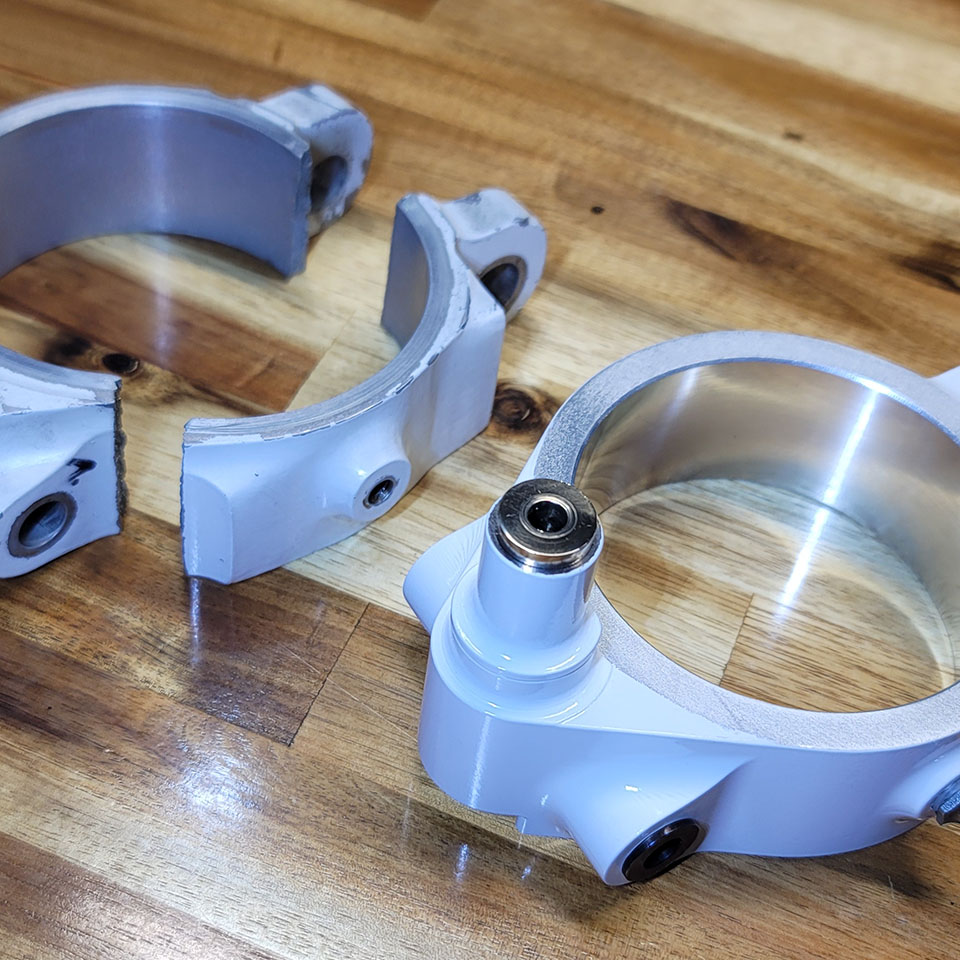

Precision CNC Machining

Our CNC division delivers production-ready parts with the accuracy, repeatability, and surface finish that today’s industries require. We machine parts up to 30″ x 40″ x 14″ and 250 lbs, using 10 palletized milling centers and multiple turning lathes to maximize throughput.

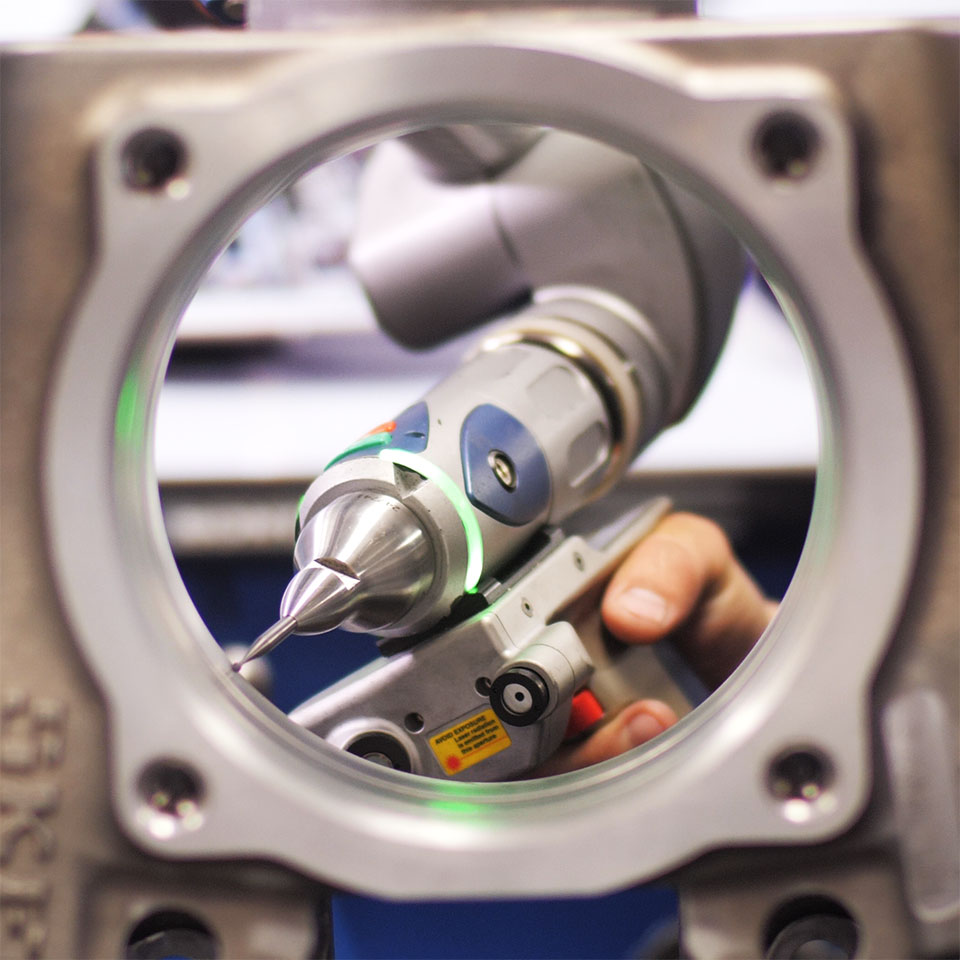

Quality and Inspection

Every machined part goes through rigorous inspection using automated CMMs, custom gauges, and in-process statistical software. From PPAP documentation to real-time dimension tracking, our ISO 9001:2015-certified team ensures consistent quality.

Reverse Engineering

Need to recreate a legacy part? Our reverse engineering services help you digitize, improve, and reproduce complex parts using 3D scanning, modeling, and manufacturing feedback.

Your Partner for Precision Machining Services

Our capabilities extend across a wide range of metals and part geometries. From castings and forgings to billet and bar stock, we apply the right process strategy for each application, backed by custom tooling, real-time inspection, and a commitment to continuous improvement.

We support:

- Multi-axis CNC milling and turning

- Cast-to-machine integration from Eagle Alloy and Eagle Precision

- Tight tolerance work (as fine as ±0.0005″)

- Surface finishes down to 8 Ra on critical features

- Complex geometries and part families with custom fixtures

With both high-speed CNC machines and operator-driven manual stations, we deliver flexible machining options designed to scale with your needs.

A Fully Integrated Manufacturing Team

As part of the Eagle Group, Eagle CNC Technologies coordinates with our casting operations—Eagle Alloy and Eagle Precision Cast Parts. This vertical integration gives you the following:

- Single-source accountability from foundry to finish

- Reduced lead times and freight costs

- Fewer production delays and handoff errors

- A team that understands casting and machining as one cohesive process

Whether you’re refining an existing design or developing a brand-new part, we bring the experience and equipment to get it done right.

Let’s Talk About Your Next Machining Project

The Eagle Group is standing by to streamline production and raise the bar on quality. We manufacture everything from tight-tolerance components to complex assemblies. Our team knows how to keep your operations running smoothly.