CNC Machining for Complex, High-Precision Parts

The Eagle Group delivers precision CNC machining services that meet the demanding requirements of industries where quality, accuracy, and speed matter most. Through our machining company, Eagle CNC Technologies, we machine high-tolerance components with repeatable accuracy from single prototypes to long-term high-volume runs.

Our in-house engineering, project management, and inspection capabilities support manufacturers from concept through completion. We help you design parts for optimal manufacturability, streamline your process, and reduce overall costs.

Precision CNC Machining Services You Can Rely On

Our machining capabilities support a wide range of part sizes, geometries, and materials. By combining automated equipment with experienced operators and digital monitoring, we produce parts that meet tight tolerances and pass rigorous inspection, every time.

We routinely support projects that require the following:

- Complex, multi-axis machining

- Machined castings from our own foundries

- Complete project management and DFM input

- Serialized inspection data and documentation

- Certified material traceability and compliance

Whether you’re launching a new design or updating legacy parts, the Eagle Group provides precision CNC machining services with end-to-end support and consistent results.

Integrated Project Support from the Start

We use a collaborative approach to machining that brings our engineers into the conversation early. From material selection and tolerance reviews to custom fixture design, we help you optimize your project before the first cut is made.

The Eagle Group’s machined parts project management includes:

- DFM and VE input at the design stage

- Custom tooling and fixture planning

- Identification of gating, datum schemes, and parting lines

- End-to-end coordination with casting and machining teams

Manufacturers choose airset molding for its balance of flexibility, durability, and cost efficiency.

Flexible Procurement and Material Sourcing

Our procurement team can source raw materials for your project or use the stock you provide. We maintain strong relationships with certified vendors and select the best-fit supplier for your job.

We support flexible sourcing models, including:

- Full procurement management

- Material provided on consignment

- Material traceability and certification on request

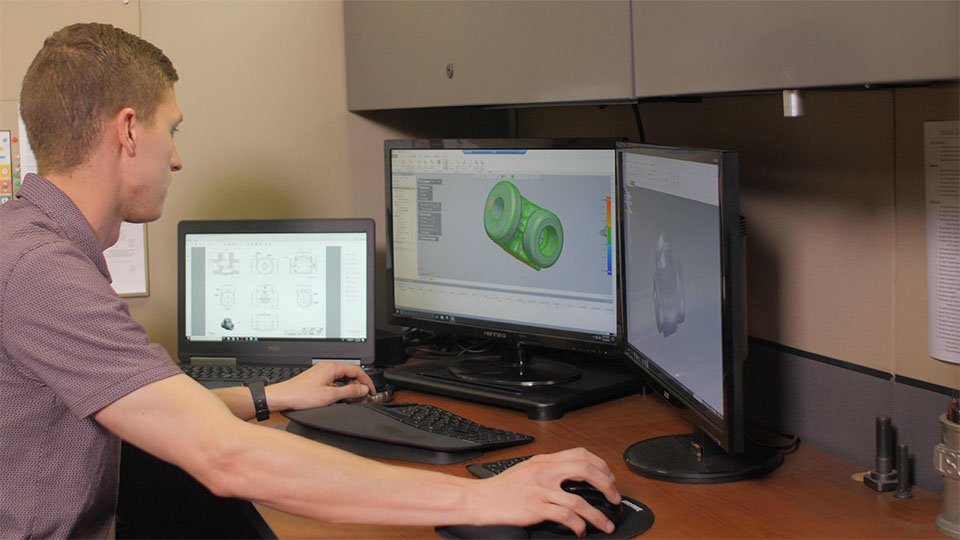

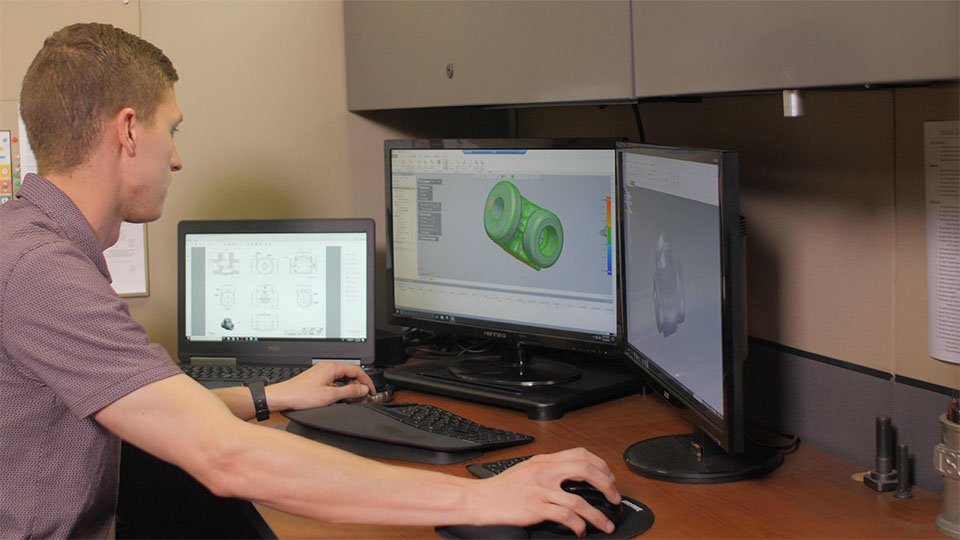

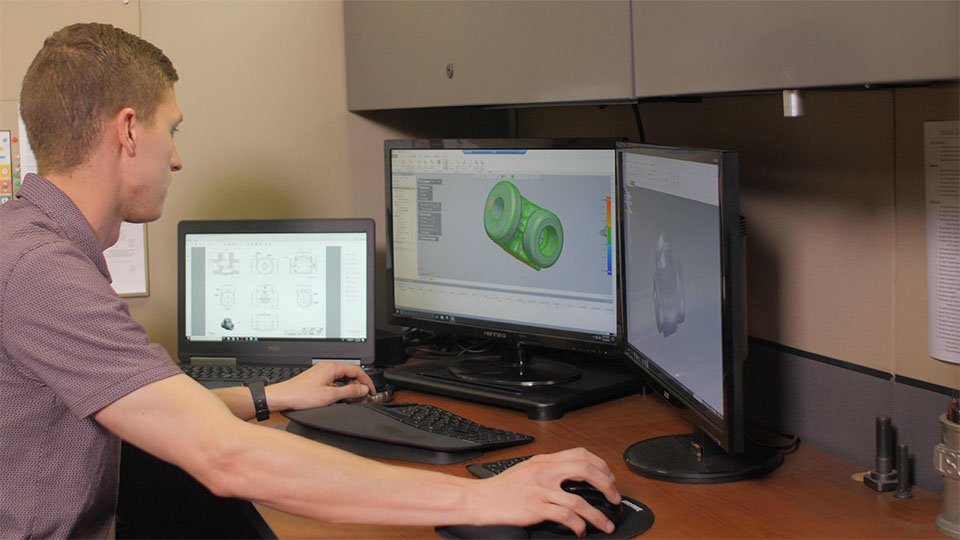

Engineering That Drives Results

Our engineers specialize in machining process design, casting integration, and Value Engineering. Using advanced software, they evaluate part geometry and production requirements to deliver a solution that reduces waste and maximizes repeatability.

Services include:

- CAD/CAM design and modeling

- Reverse engineering for legacy parts

- Toolpath optimization and workholding strategy

- Custom workholding fixtures and tool holders

- Ongoing technical support during production

Inspection and Quality Control

We monitor part quality using advanced metrology and real-time data collection. Eagle CNC Technologies integrates SPC software across nearly all work centers to ensure dimensional accuracy and fast response times.

According to our customers’ needs, the Eagle Group’s quality systems can include:

- PPAP Submissions: We provide complete Production Part Approval Process (PPAP) documentation to meet customer and industry validation requirements.

- 3D Scanning & Color Mapping: Our 3D scanning technology compares finished parts to CAD models using detailed color maps to visualize deviations.

- 100% Inspection on Production: Our parts undergo complete dimensional inspection to ensure they meet exact specifications before shipment.

- Automated CMM Inspection: We use automated coordinate measuring machines (CMMs) to capture high-precision data on part geometry and tolerances.

- Serialized Data Submission: We assign and track serial numbers with associated inspection data for complete traceability.

- Custom Gauging: We design and use custom gauges to inspect unique part features quickly and consistently during production.

- Capability Studies: Our team conducts capability studies (Cp, Cpk) to analyze process performance and verify production stability.

- Machine Certificate of Compliance: We supply certificates confirming that each part was produced and inspected to agreed-upon standards.

- Material Certifications: We provide documentation confirming material composition, source, and compliance with industry standards.

As part of the Eagle Group, Eagle CNC Technologies is ISO 9001:2015 certified. Visit our Quality page(insert link) to learn more about our inspection process and certifications.

CNC Machining Capabilities

We provide both milling and turning services for a wide range of part sizes and tolerances.

- Best Uses: Our CNC machining services are ideal for processing castings, forgings, and billet to impart close tolerances and fine surface finishes.

- Tolerances:

- Typical Linear: ±0.003″ to ±0.0005″

- Typical Radial: ±0.003″ to ±0.0001”

- Surface Finishes:

- General: 32 Ra

- Bores: 8 Ra

- Maximum Part Dimensions: 30″ x 40″ x 14″

- Maximum Part Weight: 250 lbs

Want more details?

Download our CNC Machining Equipment List

Why Choose the Eagle Group?

Working with the Eagle Group means you gain more than machining services—you gain a partner committed to quality, speed, and customer-first service. By combining foundry and machining operations under one team, we deliver value, control, and flexibility few others can match.

We support industries including:

- Aerospace

- Automotive

- Defense

- Energy

- Food Service

- Medical

- Industrial Equipment

Tight Tolerances. High Volumes. Short Lead Times.

Partner with The Eagle Group for CNC machining services that support your goals from start to finish. We’re ready to help you improve quality, reduce cycle times, and bring complex parts into production.