Reverse Engineering to Recreate & Improve Components

The Eagle Group has the ability to serve as a reverse engineering manufacturer capable of digitizing, analyzing, and reproducing existing parts without original blueprints. Whether you’re transferring parts from another casting provider, revamping worn equipment, or replicating a heritage design, we rebuild components with modern precision and proven expertise.

Why Choose Us as Your Reverse Engineering Manufacturer

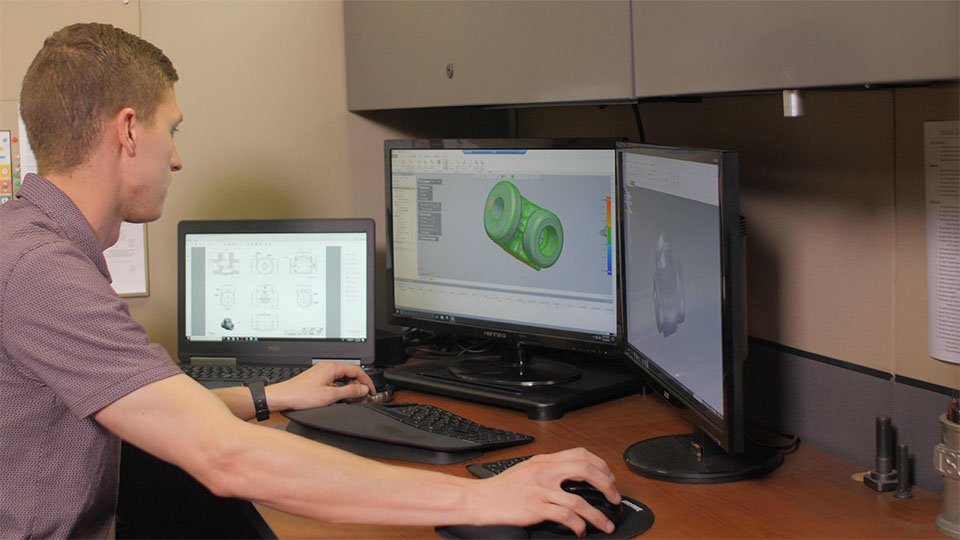

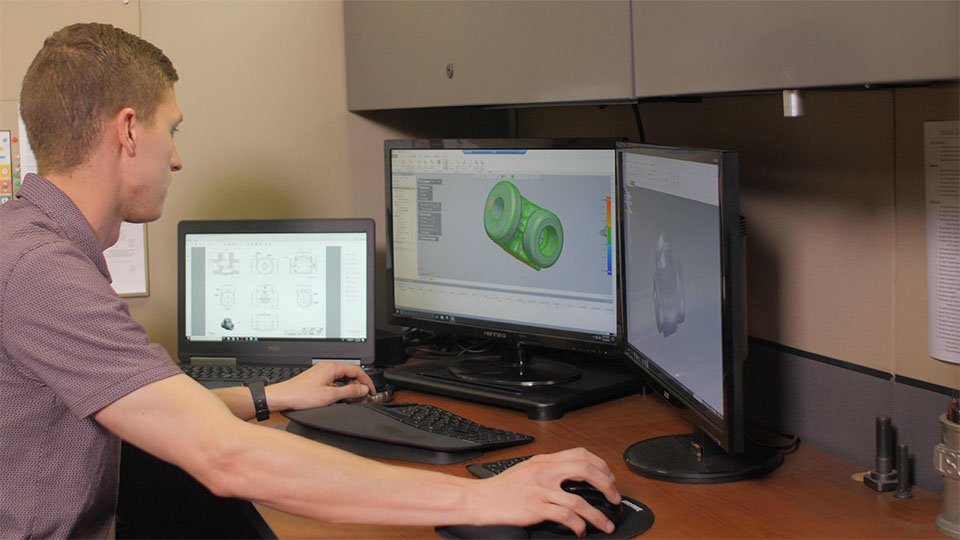

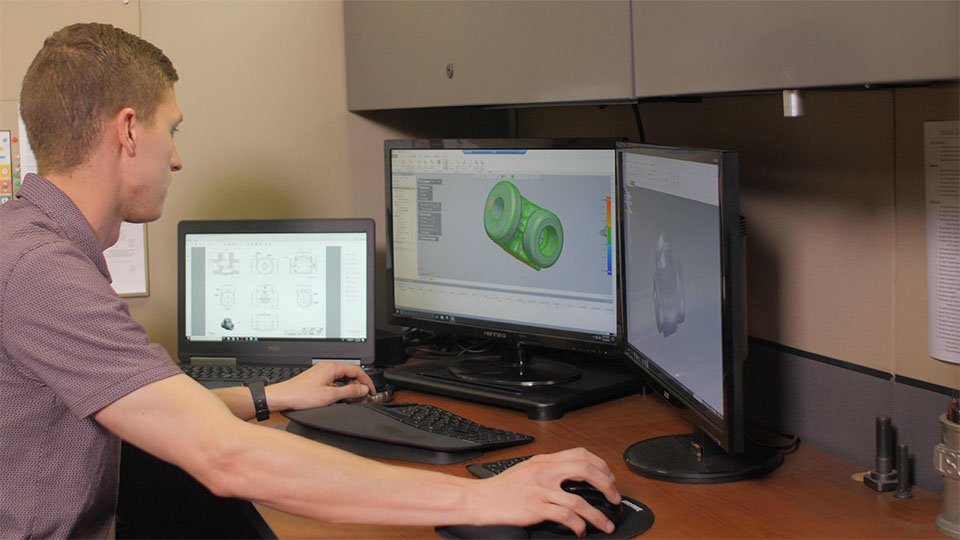

At the Eagle Group, we combine advanced 3D scanning, CAD/CAM modeling, and Precision CNC Machining to reproduce any part to exacting standards. Our collaborative teams in Eagle CNC and Eagle Alloy reconstruct geometry, optimize for Design for Manufacturability, and ensure consistent quality, resulting in fit-to-function components that meet modern specs.

How Our Process as a Reverse Engineering Manufacturer Works

Flexible Procurement and Material Sourcing

Using precision 3D scanning, we capture thousands of data points to generate an accurate CAD model—even from damaged or worn parts.

Model & Simulate

Our engineers reverse-engineer the scan data, adapt geometry for manufacturability, and run casting simulations. This ensures Design for Manufacturability and Value Engineering are applied from the start.

Cast & Machine

Combining casting and machining reduces costs through material savings. The Eagle Group supports a variety of casting methods, and will help you match the right process to your part. CNC machining finalizes each reverse-engineered component, ensuring tight tolerances and a perfect fit within existing systems.

Finishing & Validation

After machining, we can perform a comprehensive inspection, including CMM and 3D scanning to validate fit, form, and function. We also prepare PPAP and inspection reports for full traceability.

Benefits of Working with the Eagle Group

- One partner, complete capability – From castings (shell, investment, airset) to precision CNC machining.

- Easy transitions to a new casting supplier – Transfer your parts to the Eagle Group without tooling or blueprints.

- Legacy-ready processes – Perfect for discontinued parts, obsolete tooling, or products needing modernization.

- Accuracy built in – We combine scanning, simulation, Value Engineering, and full inspection to deliver parts that match or exceed original design intent.

- Resource-efficient production – Avoid expensive stock machining with our cast-then-machine route that saves time, materials, and cost.

Applications of Reverse Engineering

- Historic or discontinued metal parts

- Parts transferred from other casting suppliers

- Obsolete components lacking CAD or tool drawings

- Custom bridge parts, pump housings, and vintage machinery

- Prototypes transitioned to volume production

See How We Helped Restore the Vietnam Era Mark I PBR

A standout example of our work is the restoration of a Vietnam-era Mark I PBR pump housing, removed from a sunken boat. This was a mission rooted in legacy and detail—restoring history, honoring veterans, and showcasing true engineering prowess.

We began with careful 3D scanning of the corroded housing, creating a digital twin even though no drawings existed. Eagle Alloy used DFM and Value Engineering early in the process, running solidification simulations to confirm the stainless steel casting would fill properly. Meanwhile, Eagle CNC engineers reviewed scan data to establish nominal dimensions and custom tooling stock allowances.

Together, the teams executed the casting using 3D-printed molds and cores (insert link), followed by precision CNC machining to finalize the geometry to fit modern specs. The result: a fully functional, durable part produced in just four months—a testament to our capabilities as a reverse engineering manufacturer.

Ready to Optimize, Transition, or Restore a Critical Part?

Reverse engineering isn’t just about recreating legacy components—it’s a strategic solution for manufacturers looking to switch suppliers, change processes, or scale from prototype to production. Whether you’re recovering a hard-to-source part, transitioning from fabrication to casting, or replicating a discontinued design, the Eagle Group’s reverse engineering manufacturing capabilities ensure accuracy, efficiency, and support at every stage.