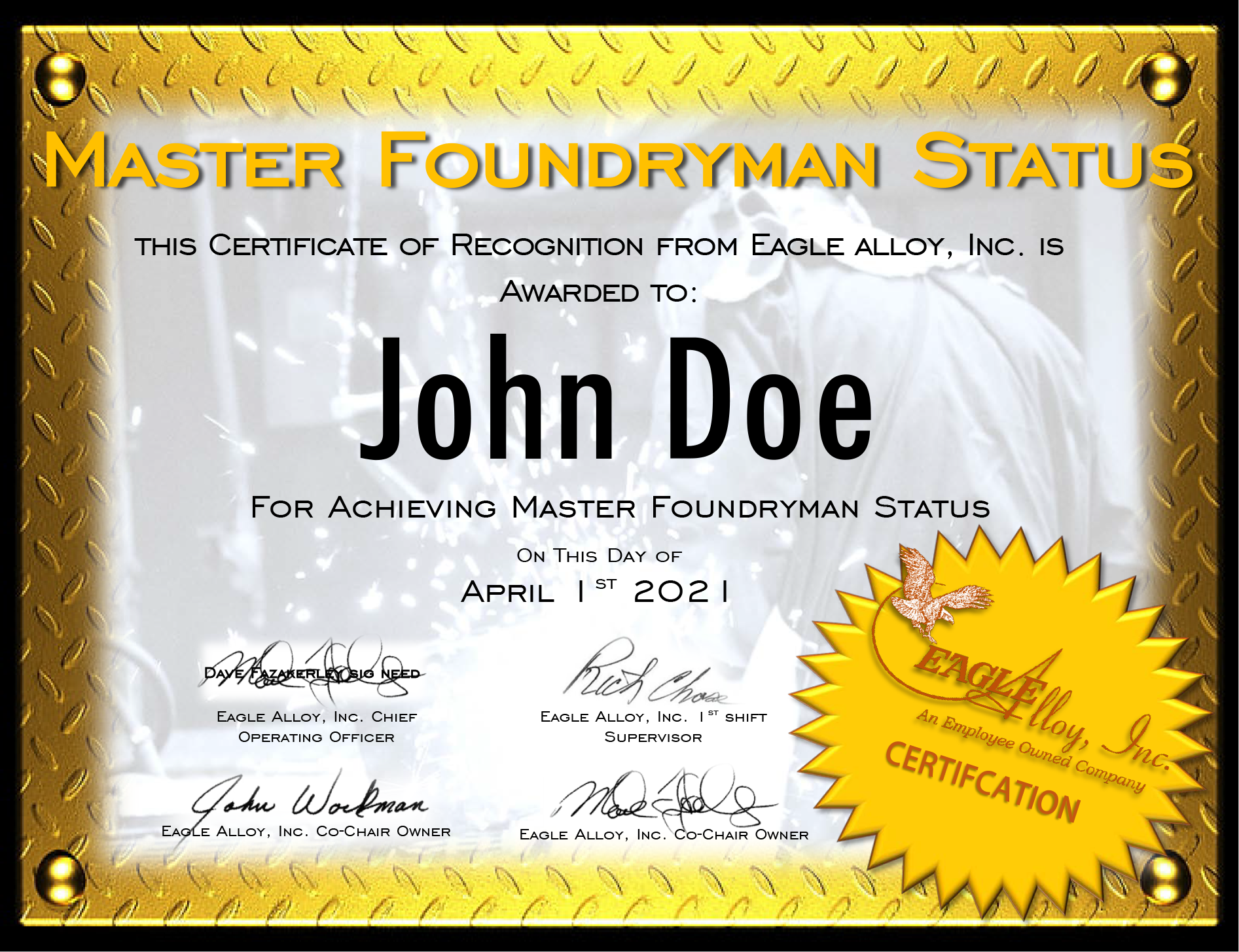

Eagle Alloy’s new internal certification program recognizes the skill and dedication of our top-performing employees. The Master Foundryman certification will be awarded every quarter based on objective measures of experience and productivity. The first Eagle Alloy Master Foundrymen, awarded following Q1 2021 performance reviews, have demonstrated consistently outstanding performance in all aspects of their jobs.

The first Master Foundryman certificate recipients include:

Pictured above, clockwise from top-left: Archice Bixby, Shawn Grawbarger, Bernard Brown, Venancio Coronado, Randy Cross, Jeffrey Tawney, Michael Tonkin

Archice Bixby

Archice Bixby

Press Operator | 1st Shift | 9+ years on the team- Bernard Brown

Shipping | 1st Shift | 15+ years on the team - Venancio Coronado

Core Operator | 1st Shift | 20+ years on the team - Randy Cross

TIG Welder | 3rd Shift | 22+ years on the team - Shawn Grawbarger

Sand Plant Technician | 1st Shift | 29+ years on the team - Jeffrey Tawney

Core Operator | 3rd Shift | 27+ years on the team - Michael Tonkin

TIG Welder | 3rd Shift | 23+ years on the team

Master Foundryman status is based on a number of criteria, including productivity, quality record, safety record, attendance and positive attitude. Each employee’s performance is reviewed by immediate supervisors, and is confirmed by Eagle Alloy’s production manager and chief operations officer. Employees who earn the certification receive recognition throughout the company, as well as ongoing financial incentives.

In order to qualify for the certification, Eagle Alloy employees must have five or more years of seniority and possess a deep knowledge of the processes involved in the job. All recipients are classified as trainers, so they not only perform their jobs with outstanding success, but they are also able to impart their experience and skill to newer employees.